Mining Casting Components

Our commitment lies in providing comprehensive solutions for the requirements of the mining and minerals industries. We specialize in manufacturing finished casting components using materials such as manganese steel, carbon steel, Ni-hard, high chrome, and stainless steel, all of which adhere to international standards. Our primary focus is on delivering top-notch quality at reasonable rates.

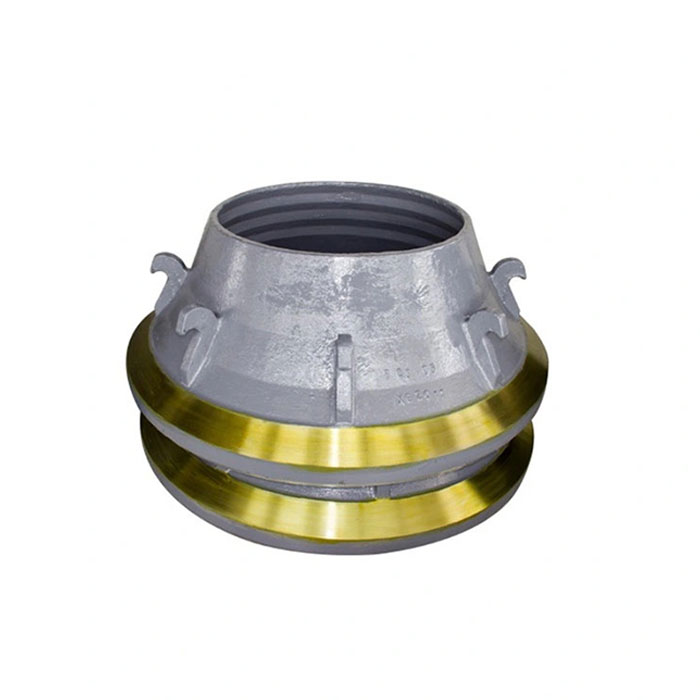

With a strong emphasis on meeting the needs of mining industries, we cater to various operations including mining and crushing, dragging and excavation, as well as ore handling, refining, and smelting. Our product range encompasses bowl and mantle liners for cone crushers of different sizes and makes.

Recognizing the critical role of cone crushers in mining operations, our engineers are dedicated to constant research and development to enhance metallurgy and improve performance. We possess proven expertise in manufacturing spare parts for crushing machines used in iron ore, zinc ore, gold, uranium, manganese ore, copper, lignite, fluorspar, and other materials. Irrespective of the material type, hardness, or the specific excavator or loader employed, whether it’s an open cast or closed mine operation, our focus remains on you and your requirements.

In addition to cone crusher components, we also produce casting components like shovel bucket teeth, crusher hammers, liners, and bucket lips. Our expertise extends to manufacturing finished casting spares for pumps of various makes and sizes, serving slurry and other applications. We are capable of manufacturing pump casings, closed impellers, and wear plates using materials such as Ni-hard, high chrome, stainless steel, and more, depending on the specifications.

Furthermore, we offer a range of casting components tailored for the mining industry.

- Jaw Plate

- Ball Mill Liners

- Concave Liners

- Impactor Hammers

- Mine Car Wheel

- Crusher Hammer

- Rim Liners

- Apron Pan

- Bucket Lips

- Sleeves

- Plannet Carrier